Medical tools and parts series (Dril)

Medical tools and parts series (Dril)

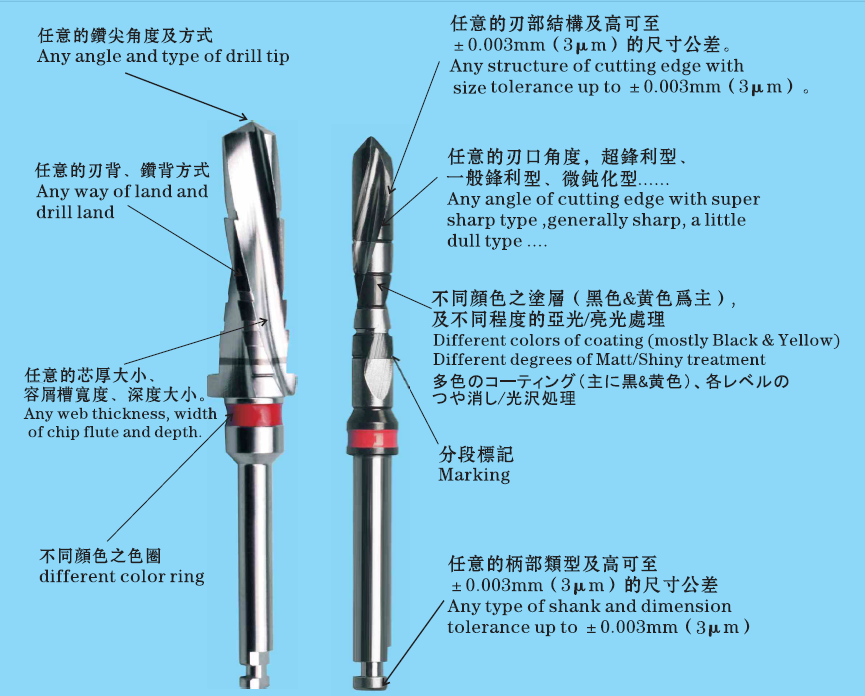

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shapes, structures, etc.

It can be produced by ultra-precision superhard grinding to mold of ceramic,tungsten steel,superhigh rust-proof high wear-resistant high-hardness stainless steel (AA), titanium, titanium alloys and other materials.

With or without penetration, hollow & hollow core inner hole process with different grades.

Different colors of coating (mostly Black & Yellow)Different degrees of Matt/Shiny treatment

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

Material of cutting edge:

1. ultra-high anti-rust high wear-resistant stainless steel(AA)(HRC54°±2°Section)(regular stock)

2. general anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section) series

3. Titanium and Titanium alloy (HRC35°~42°) series

4. Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5. Carbide(HRA81°~94°) series,(HRC60°~84°) series

※ Cutting edge machining grades:

Class AAA: CNC super hard grinding wheel, mirror surface grinding for any shape of cutting edge.Concentricity![]()

, runout![]() , cylindricity

, cylindricity![]()

≤0.003mm(3μm),any sharpness of cutting edge.

Class AA: CNC super hard grinding wheel, finish grinding for any shape of cutting edge.Concentricity![]()

, runout![]() , cylindricity

, cylindricity![]()

≤0.008mm(8μm),any sharpness of cutting edge.

Class A: CNC super hard grinding wheel, general grinding for any shape of cutting edge.Concentricity![]()

, runout![]() , cylindricity

, cylindricity![]()

≤0.012mm(12μm),any sharpness of cutting edge.

Class B: CNC lathe work + heat treatment + polishing treatment, worse sharpness of cutting edge.Concentricity![]()

, runout![]() , cylindricity

, cylindricity![]()

(0.10~0.20mm)(100/μm~200/μm).