Direction Drill,Bone Profile Drills,transplantation drills

Application domain: for implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

Direction Drill,Bone Profile Drills,transplantation drills P96

Products Description:

Application domain: for implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

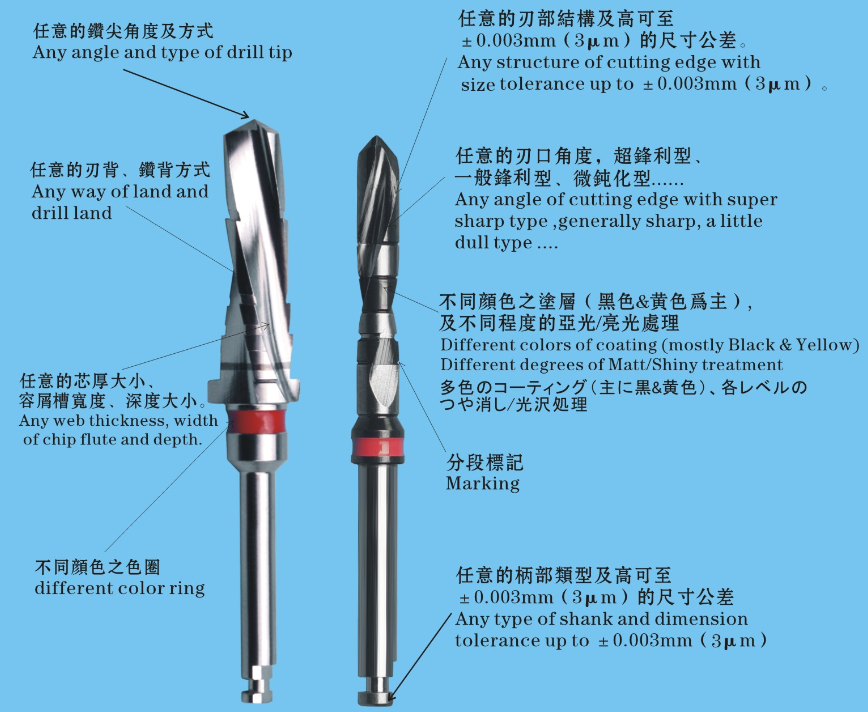

LZQ is an OEM factory for all kinds of dental implant drills, such as Guide Drill , Profile Drill, Parallel Pin, Drill Key, Lance Drill , Kirschner Wires, etc. We can also produce a whole kit of tools for customers’ surgical cases.

The cutting edge can be produced with different materials (ceramic , superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

Hollow core inner hole process grade (independent of material grade & edge process grade):

①AA grade: raw material with hole + pure mirrow grinding of hollow core inner hole (hollow core inner hole ▼▼▼▼ &R0.01) (AAA) (high cost, not commonly used)

② AA grade: raw material with holes, CFDA standard hollow core inner hole (AA) (relatively high cost, not commonly used)

③ Electrical discharge machining (EDM) process AA & A grade material + hollow core inner hole grinding (hollow core inner hole grinding grade ▼▼& ▼▼▼▼Different cost for different grade) (A&AA) (high cost, not commonly used)

④ Deep hole drilling AA&A grade material hollow core inner hole (limited by the ratio of the inner hole diameter & hole depth, conventional inner hole diameter x hole depth (30~40) times approximately) (B) (low cost, but requires batch processing)

⑤ Electrical discharge machining (EDM) processing AA & A grade raw material hollow core inner hole, the inner hole is relatively rough (C) (low cost, regular stock)