immediate extraction immediate implant drills/burs

immediate extraction immediate implant drills/burs

Products Description:

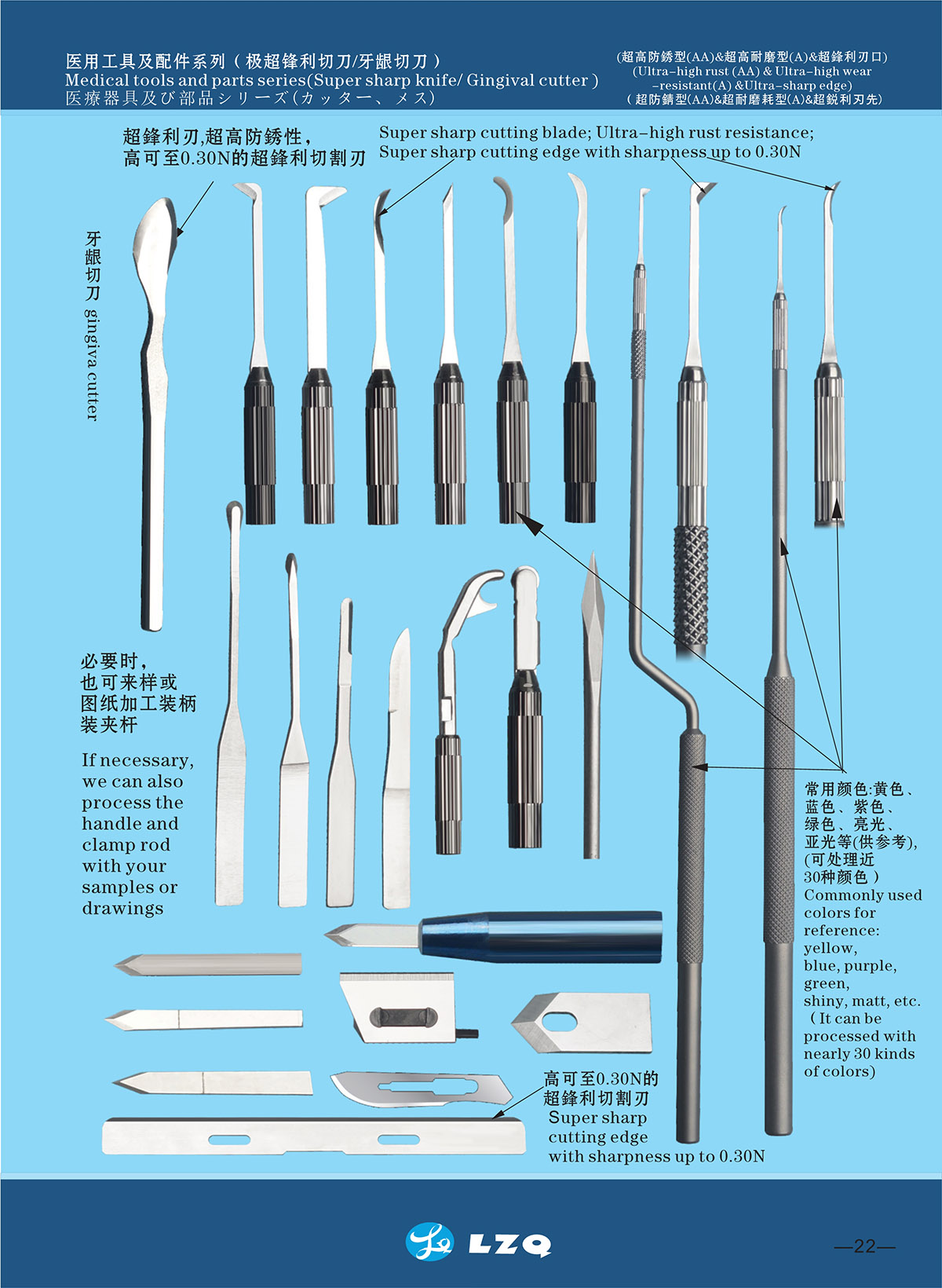

Application domain: for dental implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

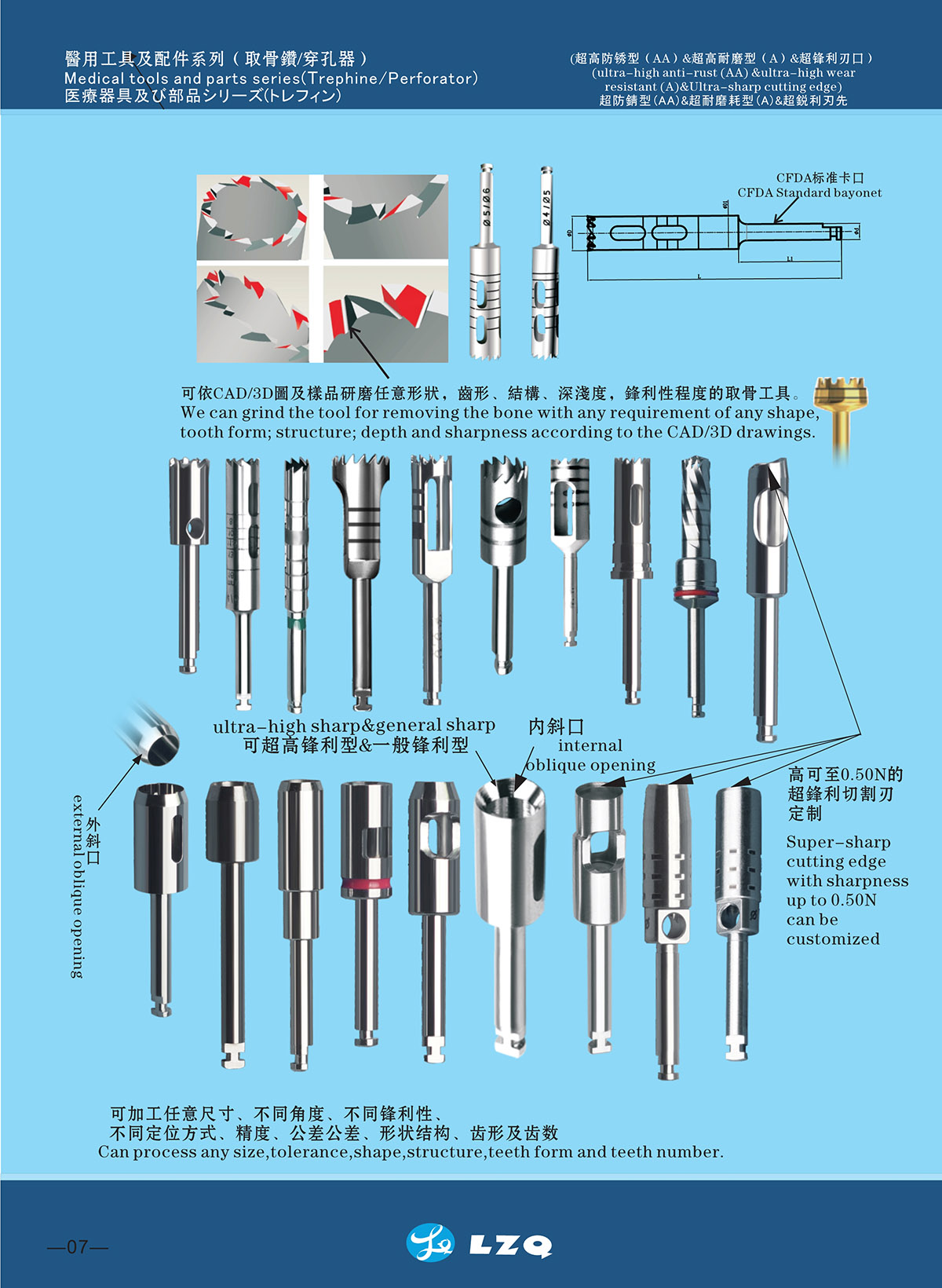

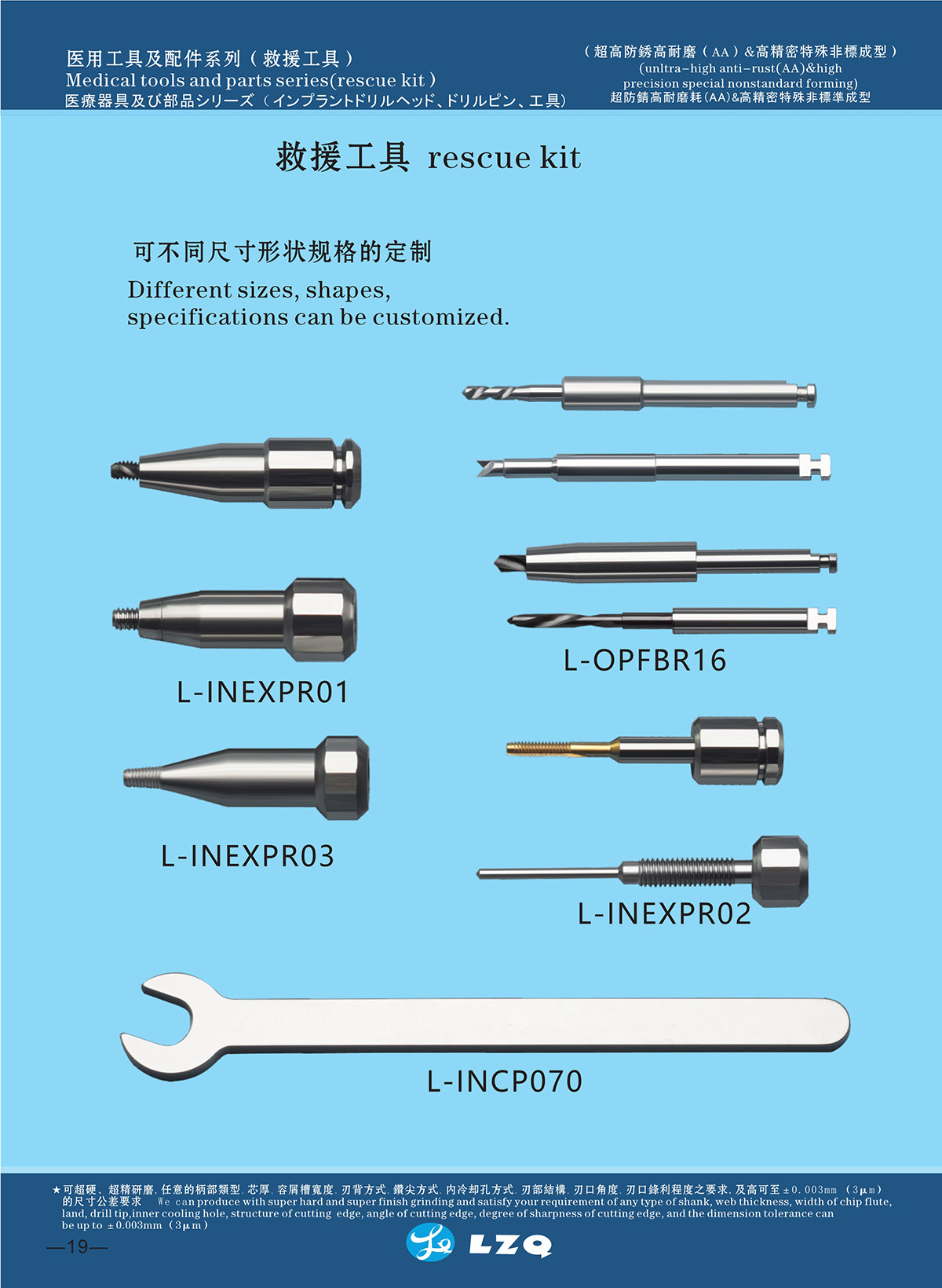

LZQ is an OEM factory that produces a variety of dental implant drills, for example, Auto Stop Cranial Perforator P222, Profile Drill P144, Bone Fetcher P165, Bone Drill Point P227, etc.

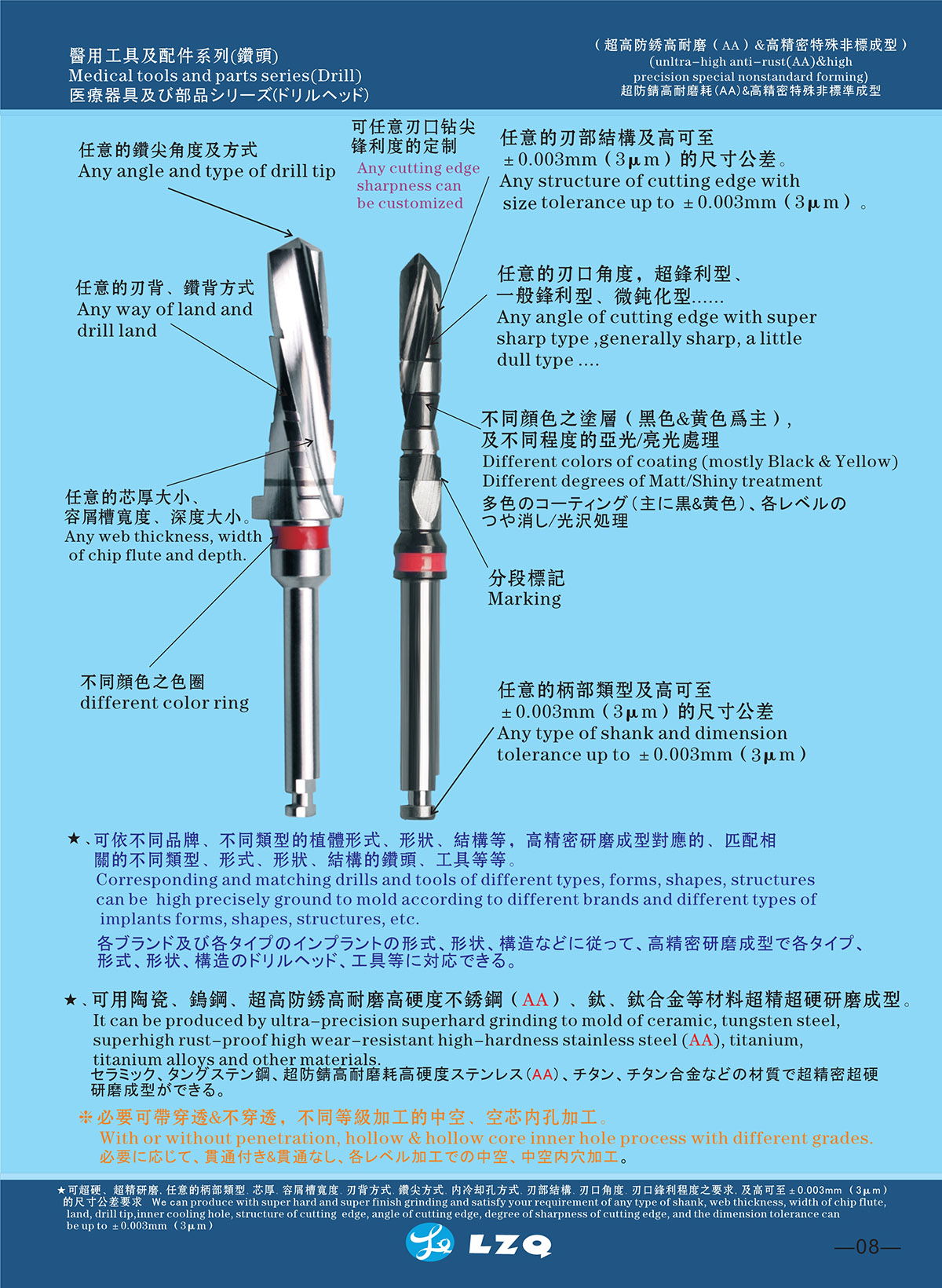

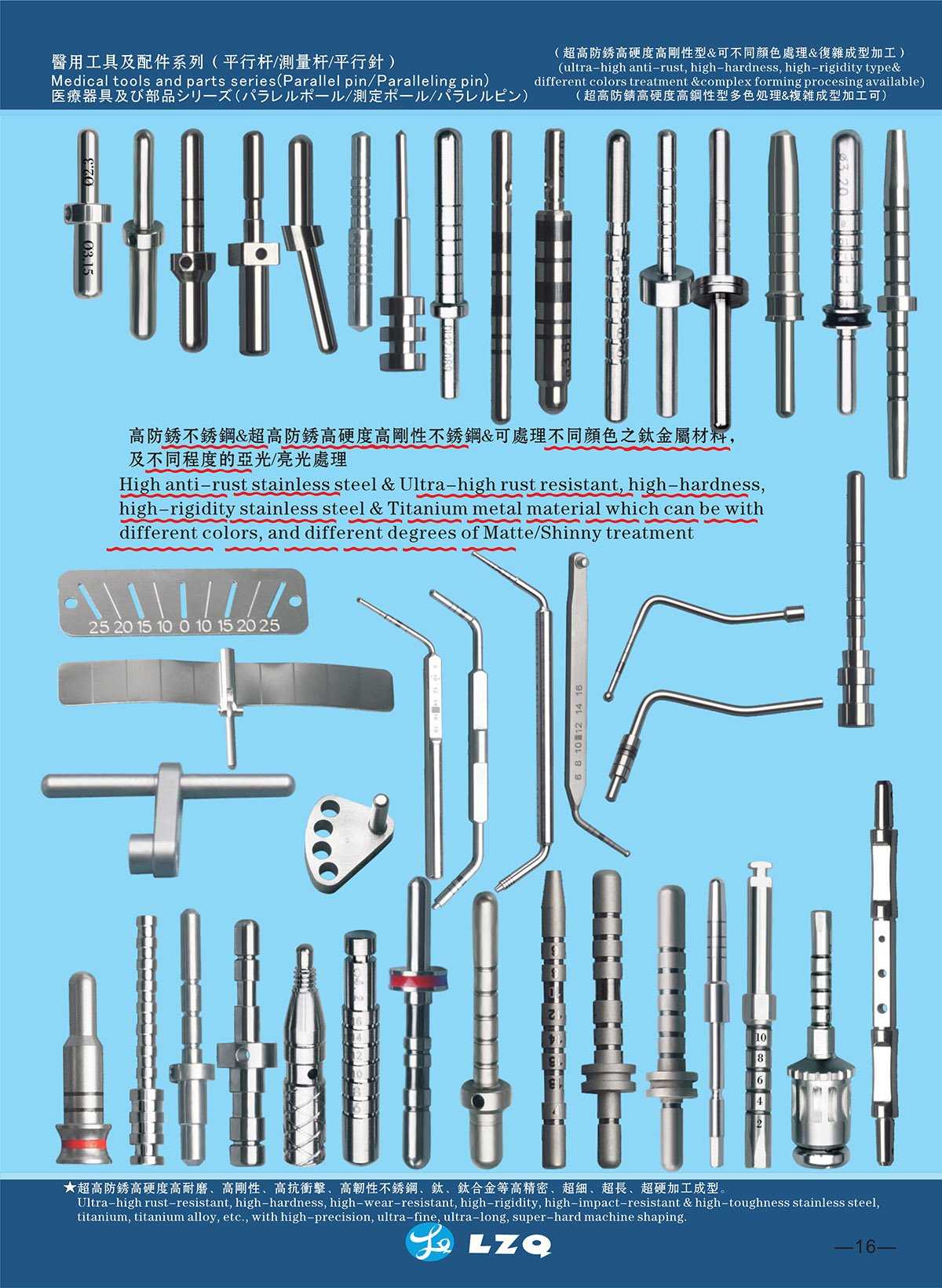

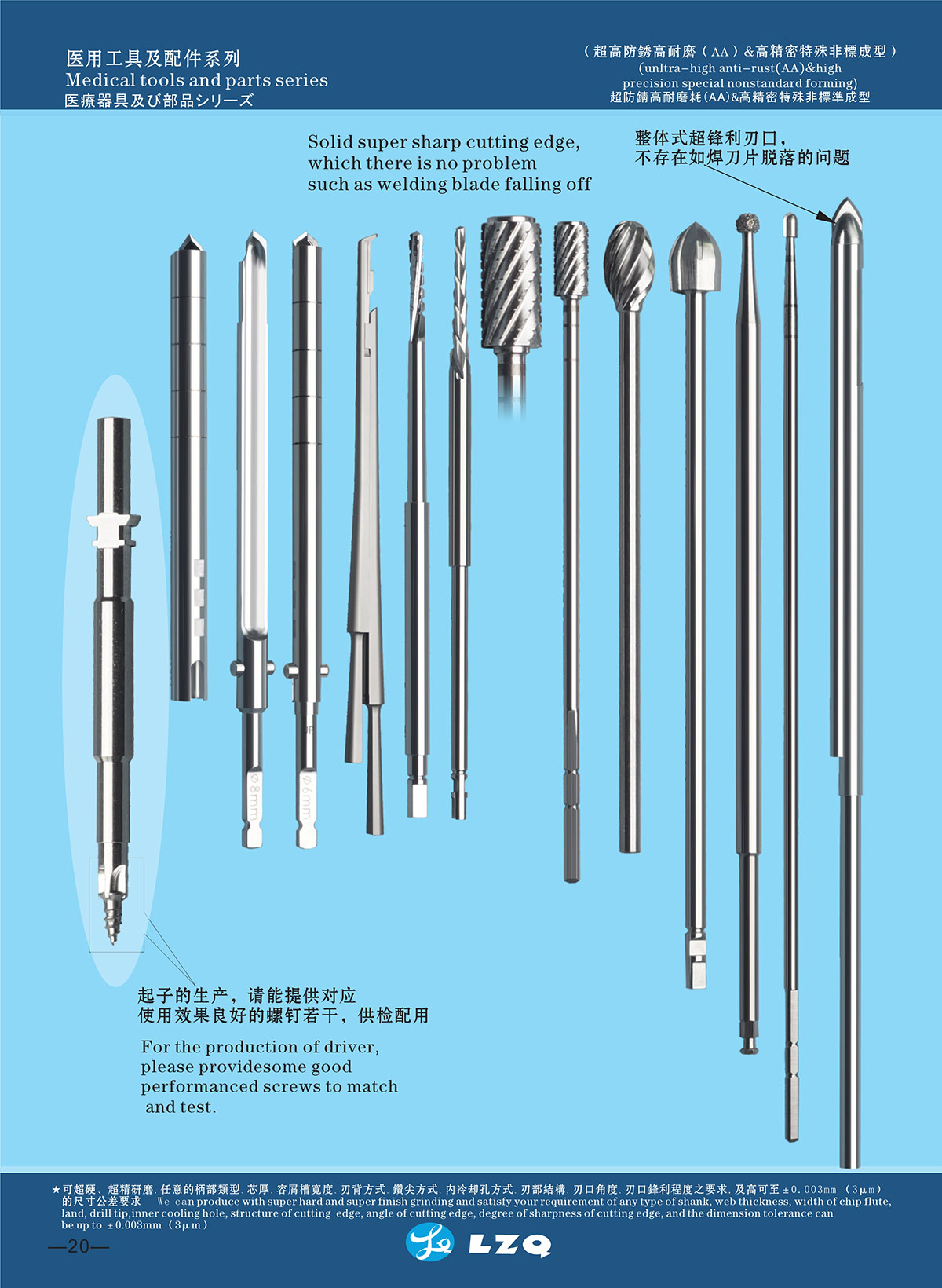

We can produce with super hard and super finish grinding and satisfy your requirement of any type of shank, web thickness, width of chip flute,land, drill tip,inner cooling hole, structure of cutting edge, angle of cutting edge, degree of sharpness of cutting edge, and the dimension tolerance can be up to ±0.003mm(3μm)

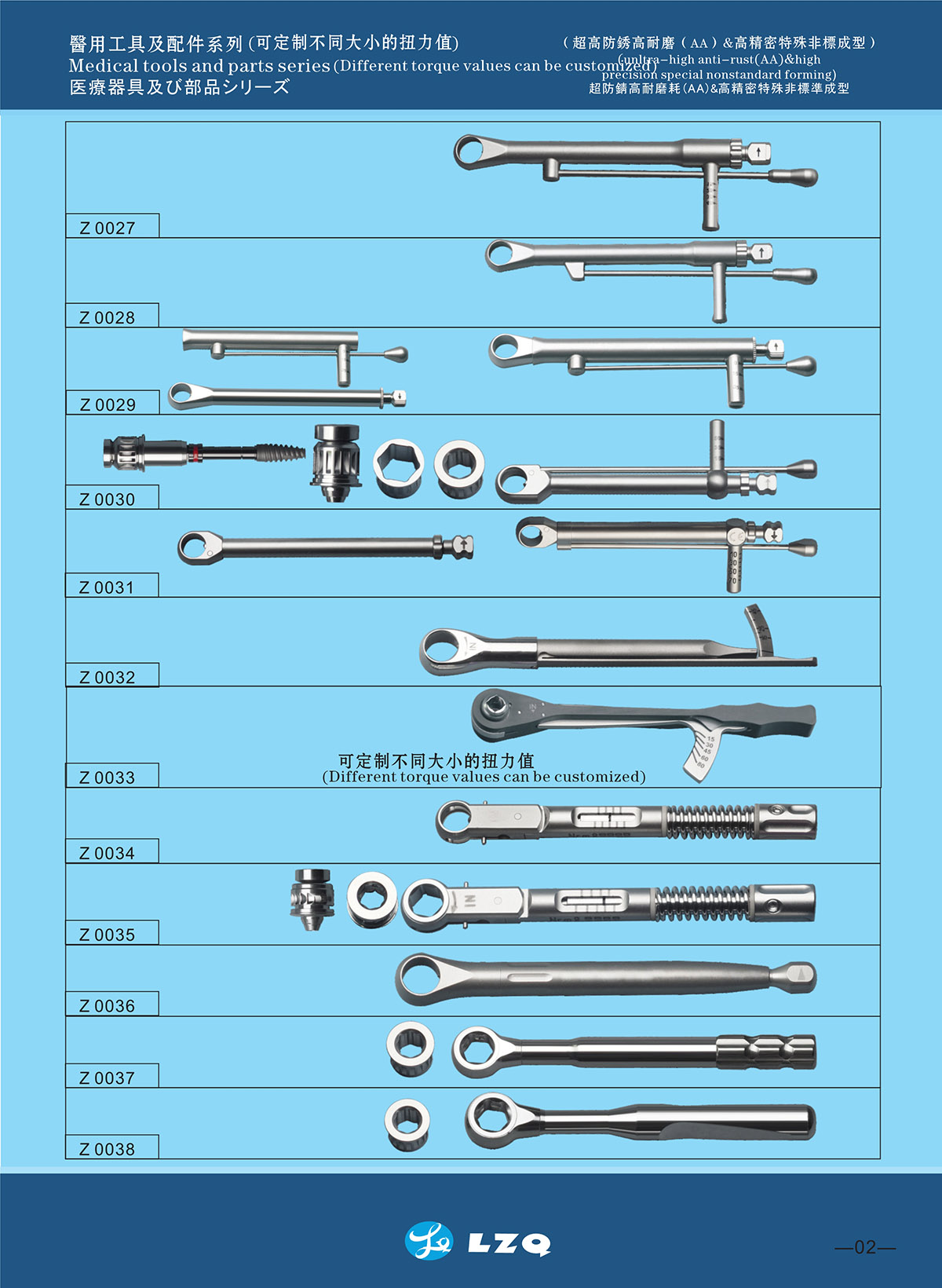

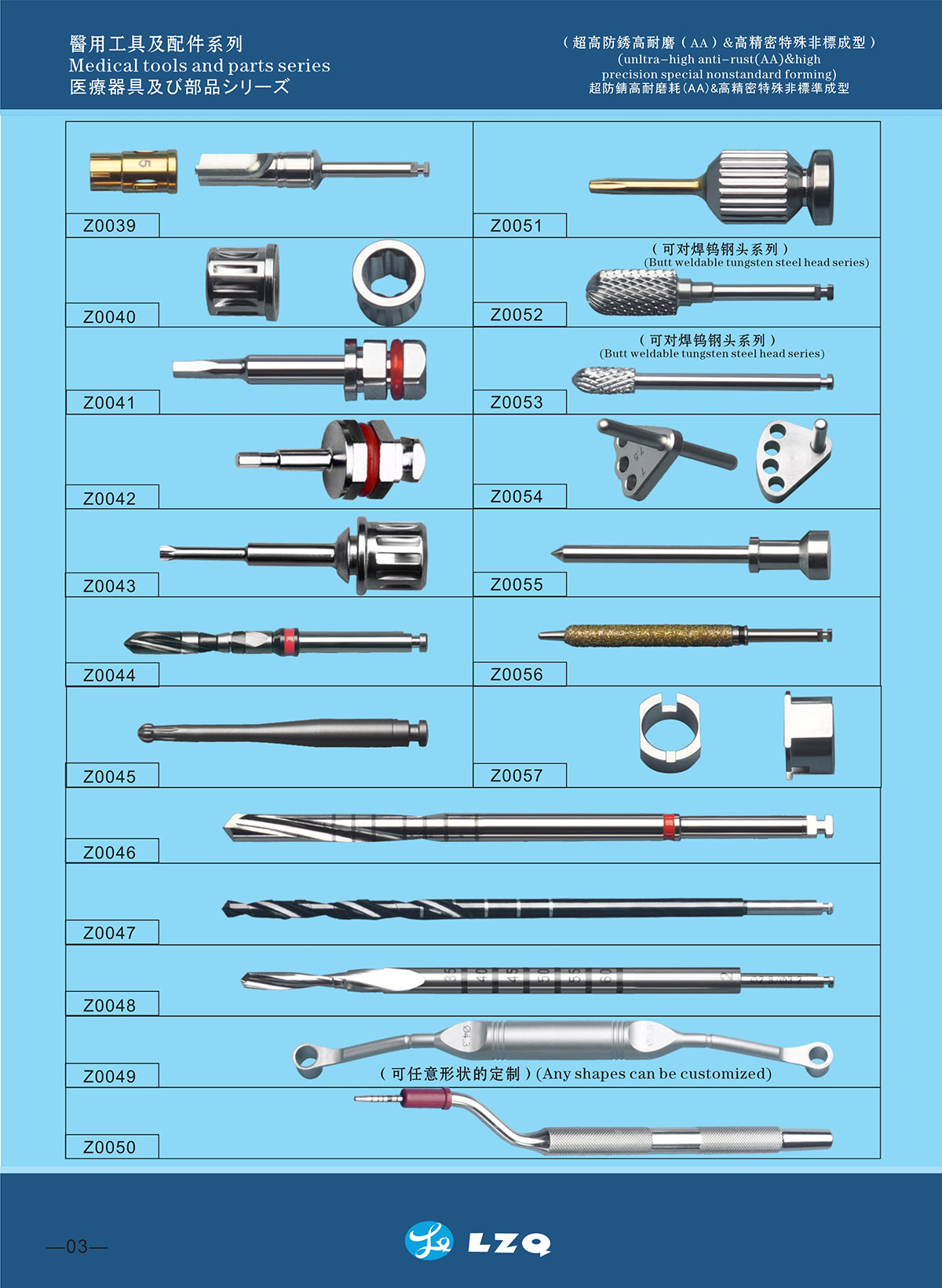

(unltra-high anti-rust(AA)&high precision special nonstandard forming)

Different colors of coating (mostly Black & Yellow),Different degrees of Matt/Shiny treatment

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

Material of cutting edge:

- ultra-high anti-rust high wear-resistant stainless steel

(AA)(HRC54°±2°Section)(regular stock)

2. general anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section) series

3. Titanium and Titanium alloy (HRC35°~42°) series

4. Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5. Carbide(HRA81°~94°) series,(HRC60°~84°) series

With or without penetration, hollow & hollow core inner hole process with different grades.

LZQ is a high-tech joint venture in the light of China's Rejuvenation, Great Harmony, Propagating health, Joyance & Sunshine... LZQ has been accumulating over 20 years of R&D experience in export-oriented medium and high-end CNC precision cutting tool, profile fixture, brazing fixtures, wear-resistant parts, high-precision accessories, super-high rust-proof & high hardness stainless steel high precision parts. Adhering to the advanced comprehensive production system, LZQ possesses various precision technology production and processing capabilities. We have introduced world first-class CNC equipment, powerful high-speed compound grinding machining center and best ultra-super-fine particle high quality raw materials, high-precision (3DX technology) molding superhard & Superfine grinding. We can achieve perfect edge quality and size tolerance up to ± 0.0005mm (± 0.5μm) in fine, ultra-long, ultra-thin, ultra-abrasive, high-impact, highly complex and combined molding processing, which can realize high-efficiency and low-cost applications! We keep annual inventory of raw materials, semi-finished products and finished products amount to 20 million~30 million RMB turnover. We can produce according to drawings or samples with a fast delivery , also a very good cost performance...