immediate implant drills/burs

immediate implant drills/burs

Products Description:

Application domain: for dental implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

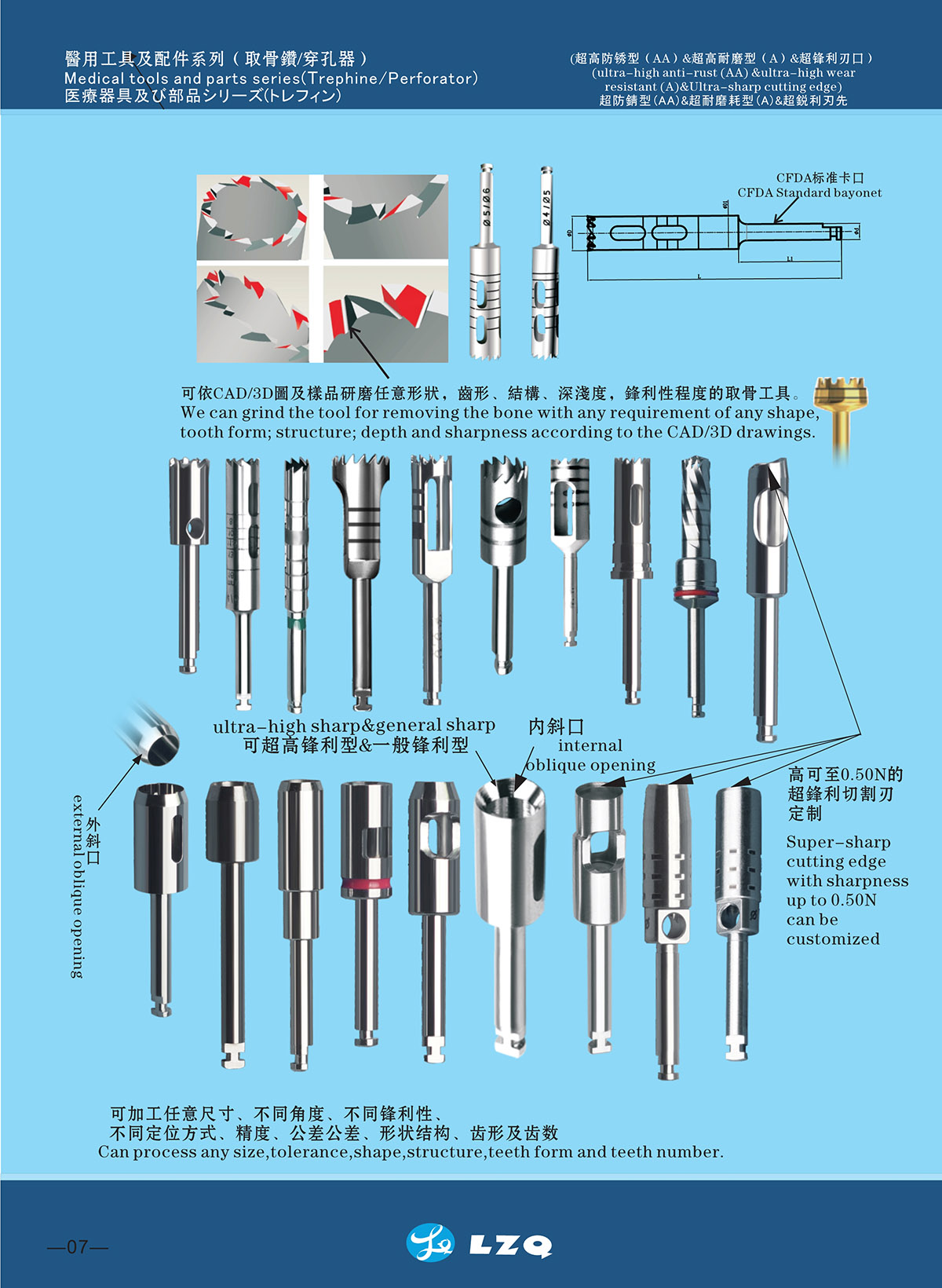

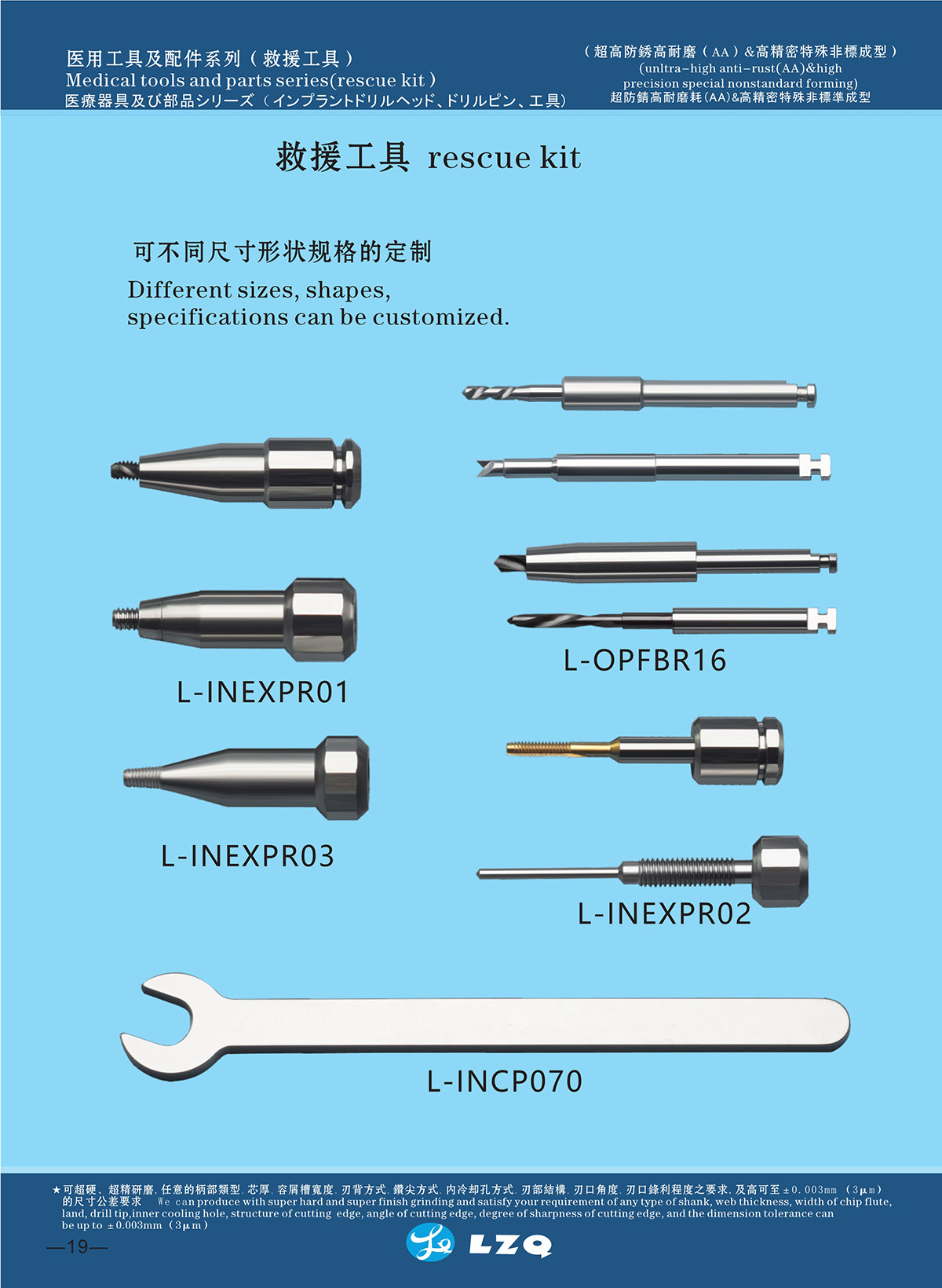

LZQ is an OEM factory that produces a variety of dental implant drills, for example, Auto Stop Cranial Perforator P222, Profile Drill P144, Bone Fetcher P165, Bone Drill Point P227, etc.

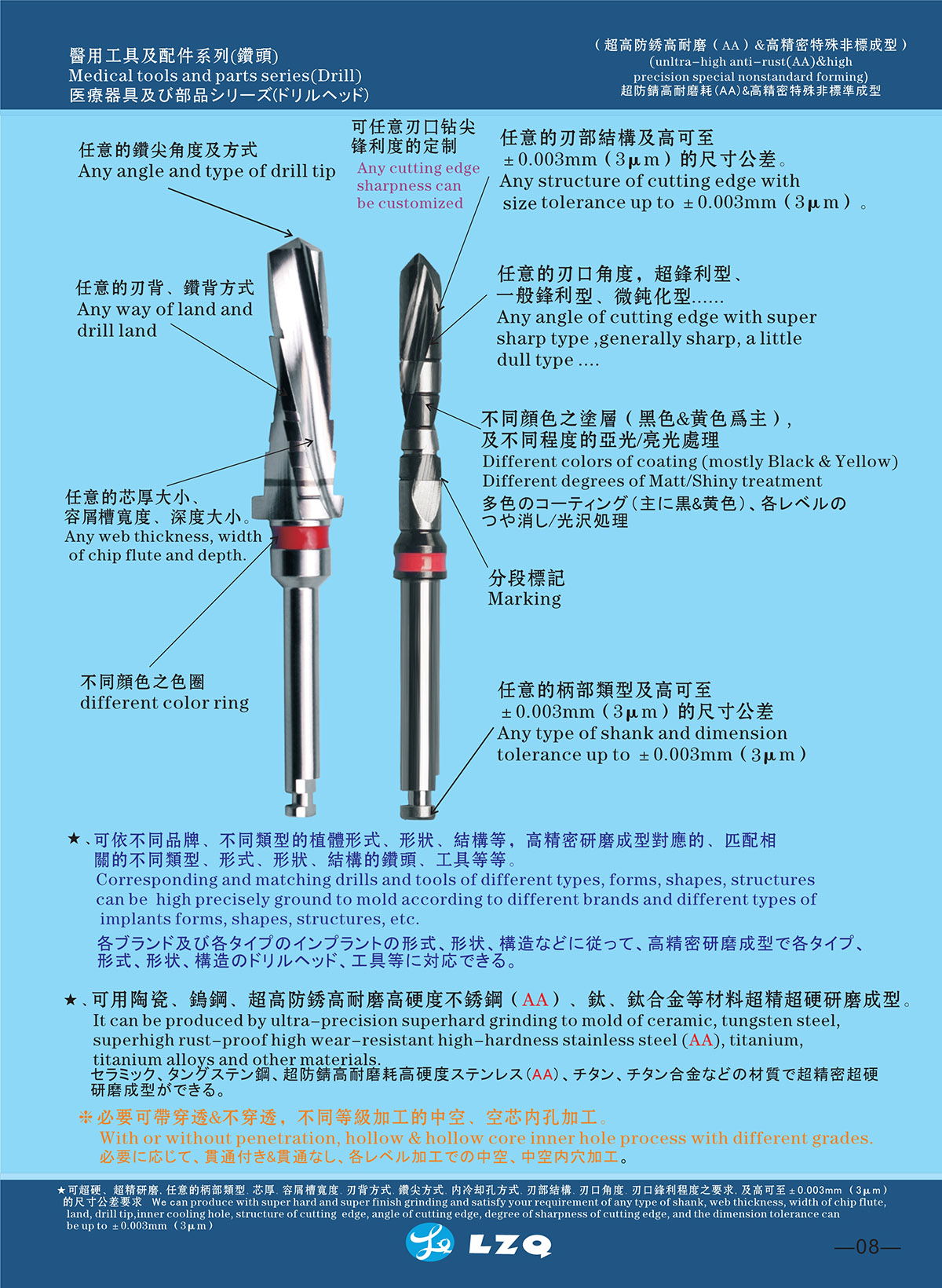

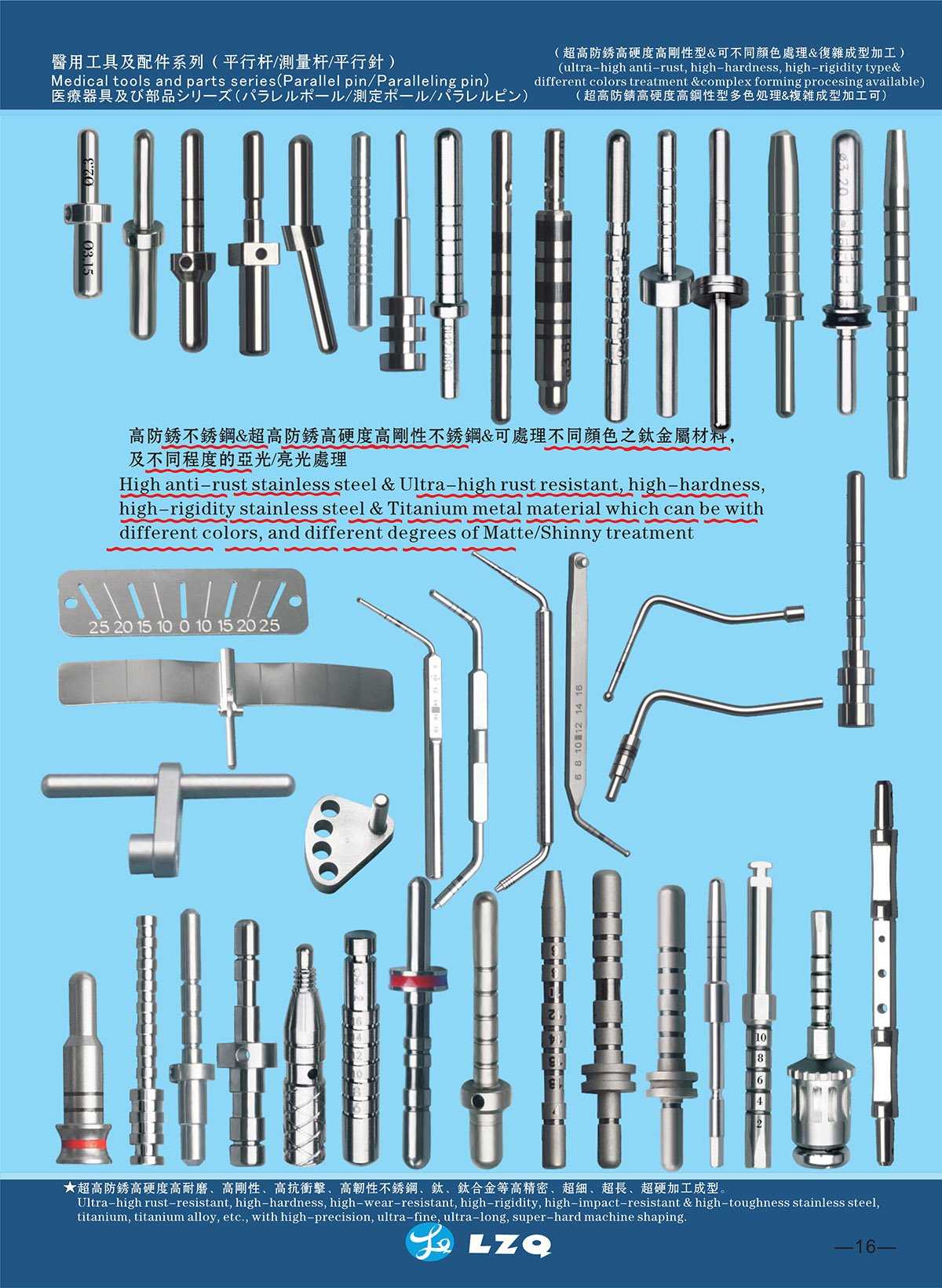

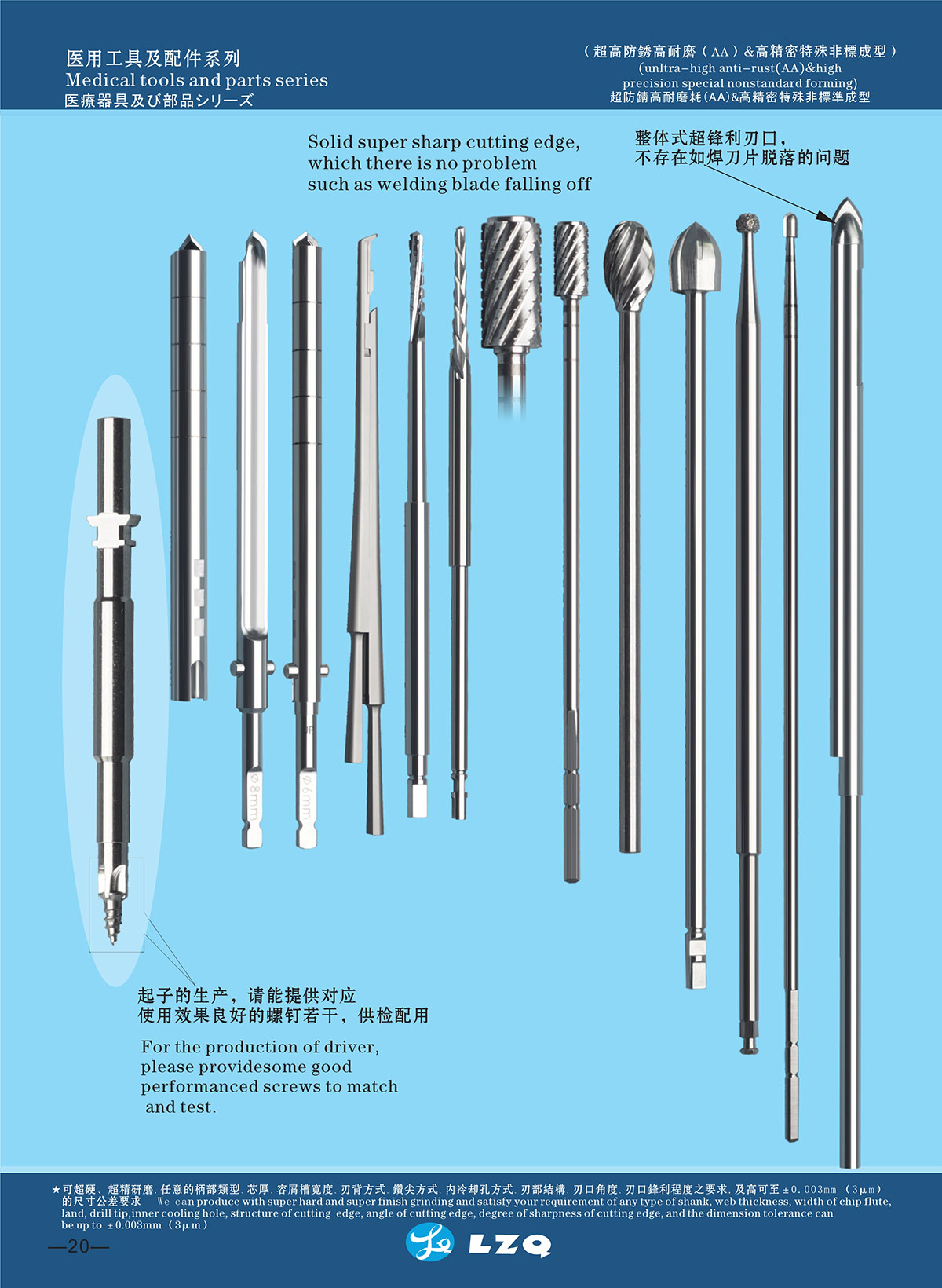

We can produce with super hard and super finish grinding and satisfy your requirement of any type of shank, web thickness, width of chip flute,land, drill tip,inner cooling hole, structure of cutting edge, angle of cutting edge, degree of sharpness of cutting edge, and the dimension tolerance can be up to ±0.003mm(3μm)

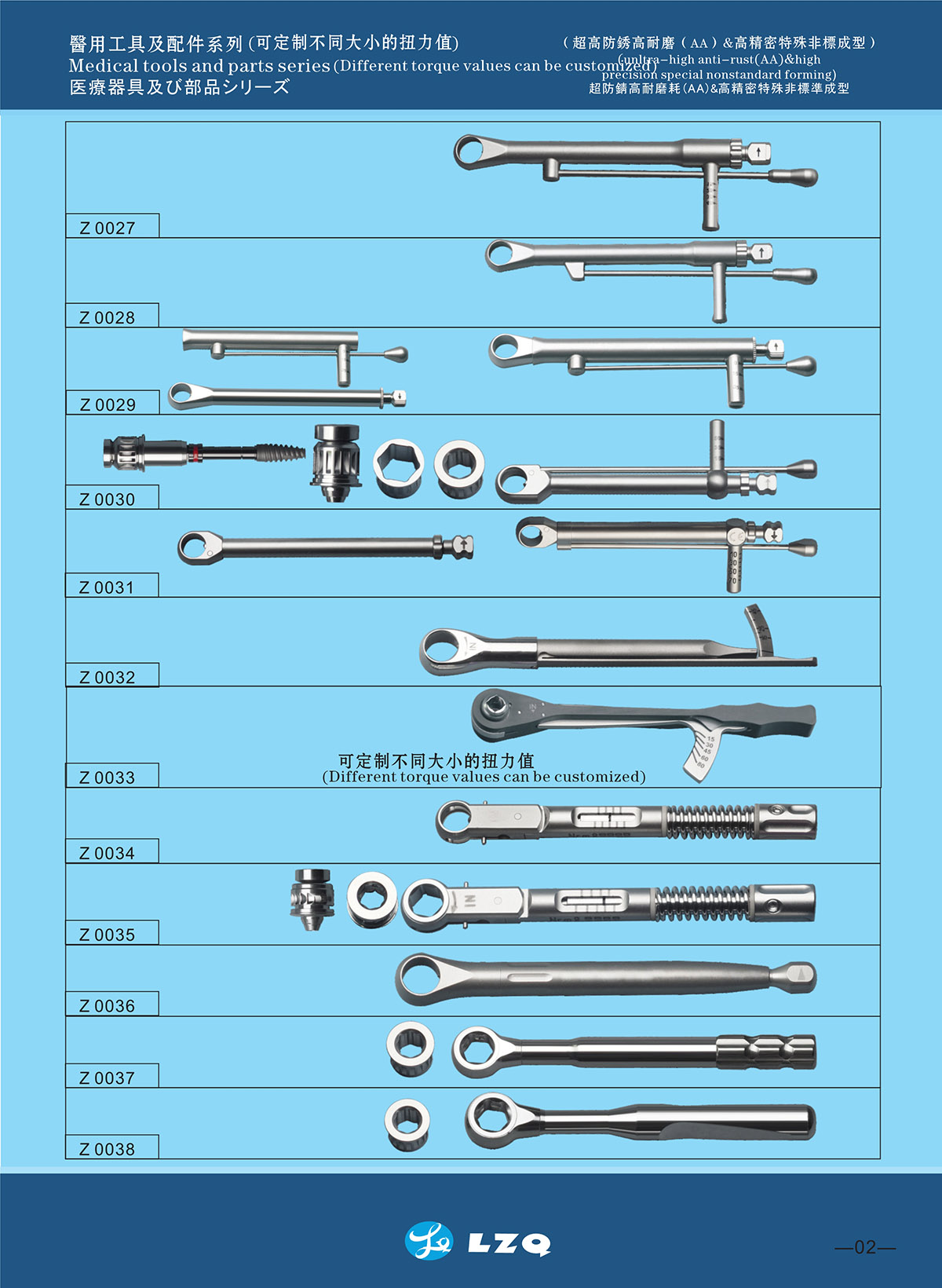

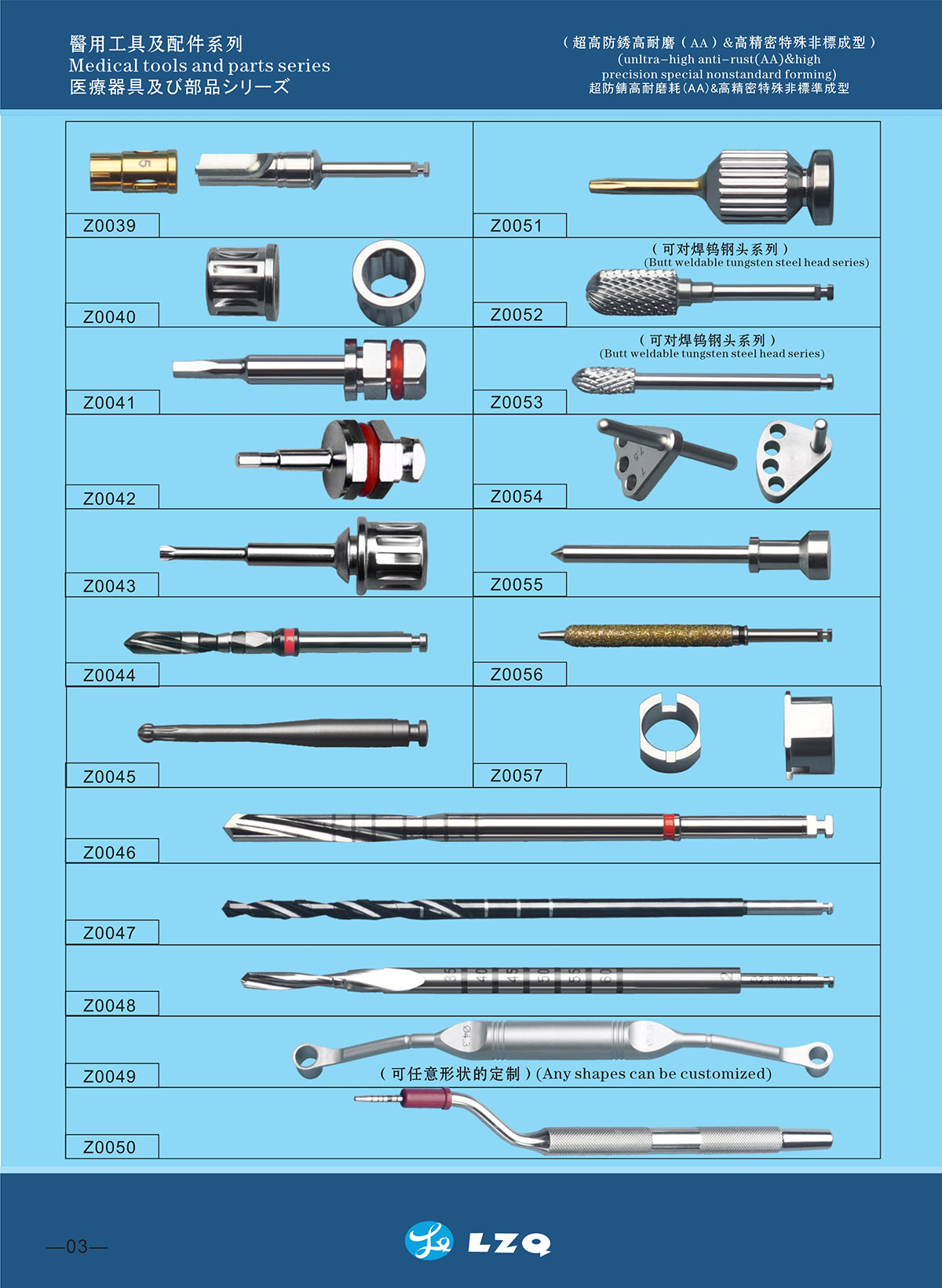

(unltra-high anti-rust(AA)&high precision special nonstandard forming)

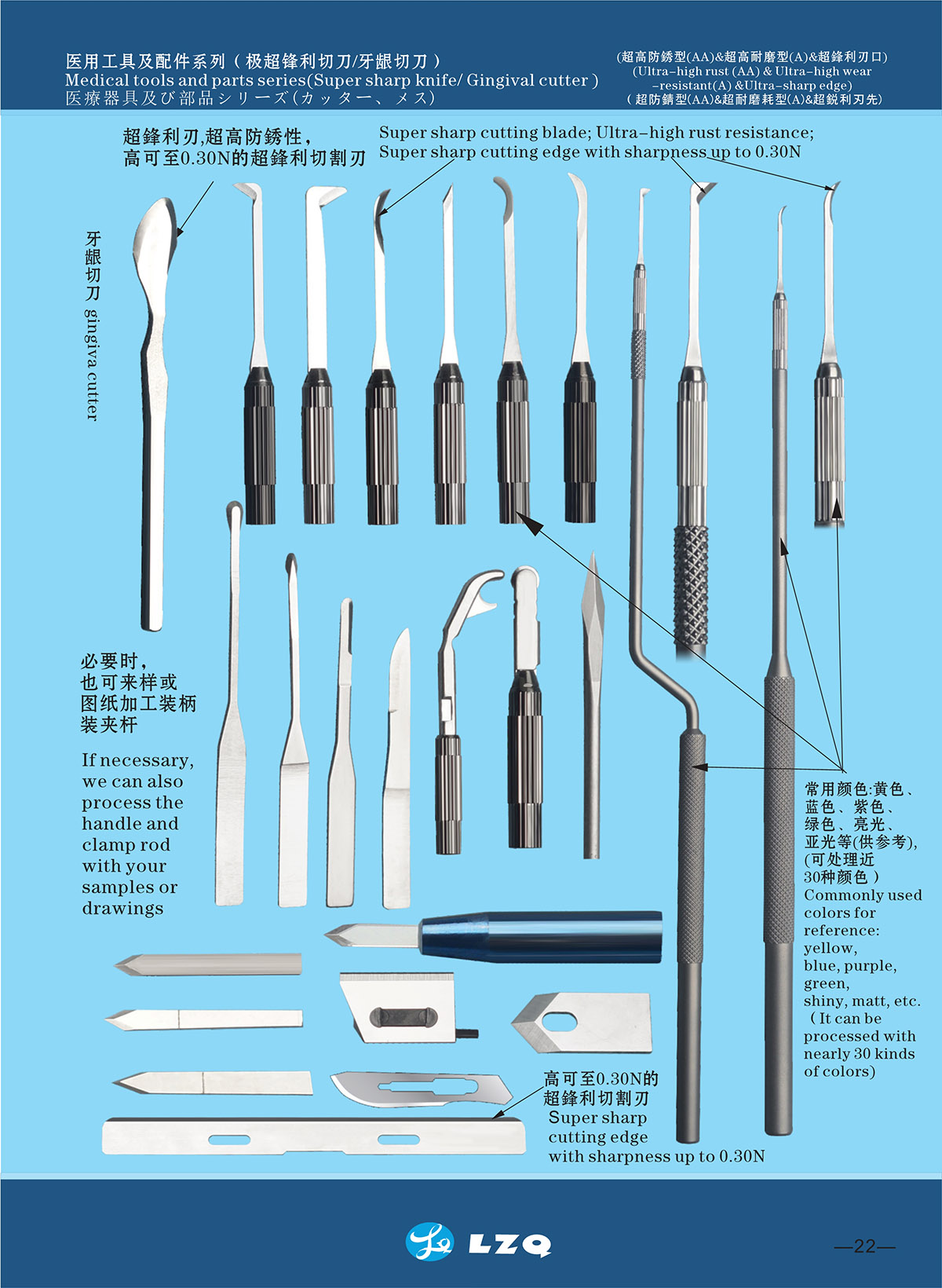

Different colors of coating (mostly Black & Yellow),Different degrees of Matt/Shiny treatment

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

Material of cutting edge:

- ultra-high anti-rust high wear-resistant stainless steel

(AA)(HRC54°±2°Section)(regular stock)

2. general anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section) series

3. Titanium and Titanium alloy (HRC35°~42°) series

4. Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5. Carbide(HRA81°~94°) series,(HRC60°~84°) series

With or without penetration, hollow & hollow core inner hole process with different grades.

Since the early days of dental implantology, osteotomies have been prepared using standard drills designed for use in industrial applications. These drill designs have proven to be functional for dental applications; implant success rates have been satisfactory over time but osteotomy preparation techniques have still been lacking for various reasons. Standard drill designs used in dental implantology are

made to excavate bone to create room for the implant to be placed. Standard drill designs, in twist or fluted shapes, cut bone effectively but typically do not produce a precise circumferential osteotomy. Osteotomies may become elongated and elliptical due to chatter of the drills. In these circumstances,the implant insertion torque is reduced, leading to poor primary stability and potential lack of integration. Osteotomies drilled into narrow bone locations may produce dehiscence, buccally or lingually, which also reduces primary stability and will require an additional bone grafting procedure, which adds cost and healing time to treatment.